X-ray fluorescence analysis, XRF of chamotte, fire clays according to DIN EN ISO 12677

Composition

A range of refractory clays with Al2O3 and SiO2 as main components.

Raw materials

Clay, kaolin or their sintered products, alumosilicates like andalusite, sillimanite, mullite as well as sintered bauxite and corundum

Fields of application

Fireclay bricks are used in furnace construction, blast furnaces, foundries in steel mills, coke ovens and gas furnaces, glass and cement industry.

- ISO 29581-2:2010-03 - Cement - Test methods - Part 2: Chemical analysis by X-ray fluorescence

- DIN EN ISO 12677:2013-02 - Chemical analysis of refractory products by X-ray fluorescence (XRF) - Fused cast-bead method

- DIN EN ISO 21068-1:2008-12 - Chemical analysis of silicon-carbide-containing raw materials and refractory products - Part 1: General information and sample preparation

- DIN EN ISO 21068-2:2008-12 -Chemical analysis of silicon-carbide-containing raw materials and refractory products - Part 2: Determination of loss on ignition, total carbon, free carbon and silicon carbide, total and free silica and total and free silicon

- DIN EN ISO 26845:2008-06 - Chemical analysis of refractories - General requirements for wet chemical analysis, atomic absorption spectrometry (AAS) and inductively coupled plasma atomic emission spectrometry (ICP-AES) methods

- DIN EN 196-2:2013-10 - Method of testing cement - Part 2: Chemical analysis of cement

- DIN EN 15309:2007-08 - Characterization of waste and soil - Determination of elemental composition by X-ray fluorescence

- DIN EN 62321-3-1:2014-10 - Determination of certain substances in electrotechnical products - Part 3-1: Screening - Lead, mercury, cadmium, total chromium and total bromine by X-ray fluorescence spectrometry

- DIN 51001:2003-08 - Testing of oxidic raw materials and basic materials - General bases of work for X-ray fluorescence method (XRF)

- DIN 51001 Beiblatt 1:2010-05 - Testing of oxidic raw materials and basic materials - General bases of work for X-Ray fluorescence method (XRF) - General survey on disintegration methods referred to groups of materials for the determination of test specimens for XRF

- DIN 51081:2002-12 - Testing of oxidic raw materials and materials - Determination of change in mass on ignition

- DIN 51418-1:2008-08 - X-ray spectrometry - X-ray emission- and X-ray fluorescence analysis (XRF) - Part 1: Definitions and basic principles

- DIN 51418-2:2015-03 - X-ray spectrometry - X-ray emission and X-ray fluorescence analysis (XRF) - Part 2: Definitions and basic principles for measurements, calibration and evaluation of results

- DIN 51719:1997-07 - Testing of solid fuels - Solid mineral fuels - Determination of ash content

- DIN 51729-10:2011-04 - Testing of solid fuels - Determination of chemical composition of fuel ash - Part 10: X-Ray Fluorescence Analysis

Analytical techniques for the analysis of chamotte, fire clay by XRF

|

||

Quantitative XRF analysis from a fused bead

Quantitative XRF analysis from a fused bead

Standard analysis for 12 oxides, applicable to all materials without without Zr-rich samples

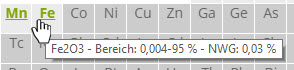

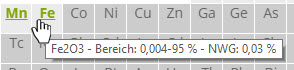

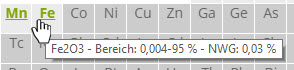

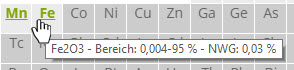

When moving the cursor over the elements highlighted in green, you will see the

- Calibration range (range) and

- the practical Limit of Detection (LOD)

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Please note:

In order to guarantee standard conformity of analysis the sample material must be ground to a grainsize < 63 µm, dried at 105°C and we need the value for the loss on ignition, LOI, as a kind of pre-preparation of the sample..

Consequently and if obligatory we carry out the sample preparation as mentioned obove - grinding, drying, determination of LOI - even though you have not explicitely ordered it.

Refer to our

► Pricelist XRF analysis

for costs and conditions.

Standard analysis for 20 oxides, applicable to all materials without without Zr-rich samples

When moving the cursor over the elements highlighted in green, you will see the

- Calibration range (range) and

- the practical Limit of Detection (LOD)

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Please note:

In order to guarantee standard conformity of analysis the sample material must be ground to a grainsize < 63 µm, dried at 105°C and we need the value for the loss on ignition, LOI, as a kind of pre-preparation of the sample..

Consequently and if obligatory we carry out the sample preparation as mentioned obove - grinding, drying, determination of LOI - even though you have not explicitely ordered it.

Refer to our

► Pricelist XRF analysis

for costs and conditions.

Standard analysis for 30 elements/oxides, applicable to all materials without without Zr-, Mn, Cr-rich samples

When moving the cursor over the elements highlighted in green, you will see the

- Calibration range (range) and

- the practical Limit of Detection (LOD)

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Pleas note:

In order to guarantee standard conformity of analysis the sample material must be ground to a grainsize < 63 µm, dried at 105°C and we need the value for the loss on ignition, LOI, as a kind of pre-preparation of the sample..

Consequently and if obligatory we carry out the sample preparation as mentioned obove - grinding, drying, determination of LOI - even though you have not explicitely ordered it.

Refer to our

► Pricelist XRF analysis

for costs and conditions.

Standard analysis for 40 elements/oxides, applicable to all materials without without Zr-, Mn, Cr-rich samples

When moving the cursor over the elements highlighted in green, you will see the

- Calibration range (range) and

- the practical Limit of Detection (LOD)

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Please note:

In order to guarantee standard conformity of analysis the sample material must be ground to a grainsize < 63 µm, dried at 105°C and we need the value for the loss on ignition, LOI, as a kind of pre-preparation of the sample..

Consequently and if obligatory we carry out the sample preparation as mentioned obove - grinding, drying, determination of LOI - even though you have not explicitely ordered it.

Refer to our

► Pricelist XRF analysis

for costs and conditions.

Quantitative analysis of a fused bead for 12, 16, 20 or 40 elements according to DIN ISO 12677:2012, DIN EN 15309:2007

For the analysis of oxide and oxidizable samples composed of a wide range of different materials such as, for instance, glass and glass fibres, soils, rock, mineral raw materials, ceramic or mineral-bonded construction materials etc.

This process involves adding a flux, lithium tetra borate, to the sample material, followed by fusing in an oxidizing atmosphere after which the sample is rapidly cooled down to form a homogenous fused bead, which is then analysed with utmost precision.

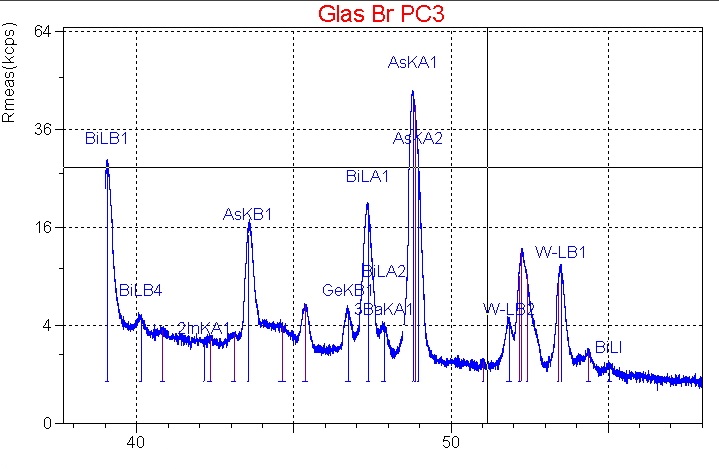

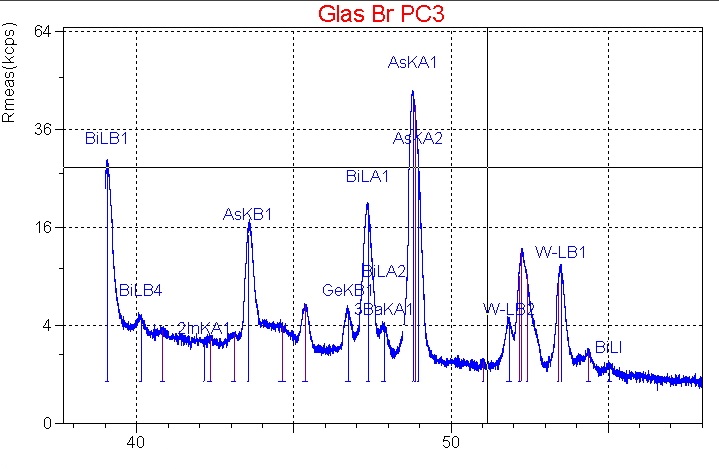

Screening analysis for 71 oxides/elements

Screening analysis for 71 oxides/elements

Screening analysis on 71 oxides/elements. Limit of detection 250 µg/g

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Please note:

In order to guarantee standard conformity of analysis the sample material must be ground to a grainsize < 63 µm, dried at 105°C and we need the value for the loss on ignition, LOI, as a kind of pre-preparation of the sample..

Consequently and if obligatory we carry out the sample preparation as mentioned obove - grinding, drying, determination of LOI - even though you have not explicitely ordered it.

Refer to our

► Pricelist XRF analysis

for costs and conditions.

The fundamental parameter programme Omnian provides a matrix-independent, quantitative, semi-quantitative or qualitative XRF analysis of unknown samples with a variety of material properties and different organic and inorganic compositions.

The fundamental parameter programme Omnian provides a matrix-independent, quantitative, semi-quantitative or qualitative XRF analysis of unknown samples with a variety of material properties and different organic and inorganic compositions.

Samples can be analyzed either after preparation or without preparation and non-destructively in case of a suitable composition, i.e. X-ray and vacuum stable and depending on their surface condition.

This enables us to determine element concentrations between the minimum detection limit, usually 250 µg/g and 100%.