Interesting facts from A to Z around asbestos analysis and X-Ray fluorescence analysis

Following are explanations of terms and abbreviations, guidelines and norms concerning the topics asbestos analysis and XRF-analysis.

Actinolite

Monoclinic amphibole asbestos with the formula Ca2(Fe2+,Mg)5[OH|Si4011)2.

High-iron mixed crystal made from ferrous actinolite – tremolite – series of mixed crystal.

Application like amosite.

Can be contained in road pavings as a natural component of magmatic rocks like basalt, dibase or gabbro, which are used for the production of grit.

Amosite

(Grunerite, brown asbestos), monoclinic amphibole asbestos with the chemical formula (Fe2+,Mg)7Si8O22(OH)2.

Forms brown or green fibrous crystals.

Application: protective clothing against heat, fire resisting plates, sprayed materials, paints, floorings, seals, brake linings, clutch linings, asbestos cement products -plates, pipes, corrugated plates, flower boxes, vent pipes- glues - lutings, putties, diatomaceous earth.

Can be contained in road surfaces as a natural component of magmatic rocks like basalt, dibase or gabbro, which are used for the production of grit.

Antophyllite

Orthorhombic amphibole asbestos with the chemical formula (Mg,Fe2+)7Si8O22(OH)2

Application like amosite.

Asbestos - ambient air measurement

Analysis of ambient air - release measurements, success control measurements, status – quo measurements during an asbestos abatement - is carried out according to guidelines VDI 3492, VDI 3861, part 2, GBI 505-46, ISO 14966 for the presence of asbestos and MMMF.

CRB GmbH does not carry out on-site ambient air measurements, but we analyse monitors you send for analysing. We also provide you with monitors equipped with membrane filters.

Asbestos - Ban on ...

Heat resistant asbestos glove - Image source Wikimedia Commons: LukaszKatlewa (https://commons.wikimedia.org/wiki/File:Heat-resistant_asbestos_glove.jpg), „Heat-resistant asbestos glove“, https://creativecommons.org/licenses/by/3.0/legalcode

Heat resistant asbestos glove - Image source Wikimedia Commons: LukaszKatlewa (https://commons.wikimedia.org/wiki/File:Heat-resistant_asbestos_glove.jpg), „Heat-resistant asbestos glove“, https://creativecommons.org/licenses/by/3.0/legalcode

Being harmful to health the use of asbestos fibres in Germany was gradually restricted. In 1979 the use of sprayed asbestos was banned, in 1982 the production and use of asbestos-containing floorings and in 1993 there was a general ban on their production and sale according to the Chemicals Regulation.

Restrictions since 1979

- 1979 Use of sprayed asbestos - German prevention regulation VBG 119

- 1982 Production and use of asbestos-containing floorings - Ordinance on Hazardous Substances

- 1984 Asbestos in night-storage heaters

- 1991 Use of asbestos-cement products

- 1993 Use and sale of asbestos – Chemicals Regulation

- 1994 Production of pressure pipes

- 1995 Use of pressure pipes

Image source Wikimedia Commons: LukaszKatlewa, Heat-resistant asbestos glove, CC BY 3.0

Asbestos - containing floorings

Vinyl-asbestos-floorings, Dunloplan - Image source Wikimedia Commons Tim Ebert (tebert) (https://commons.wikimedia.org/wiki/File:Dunloplan_Pastell-Polyflex.jpg), „Dunloplan Pastell-Polyflex“, https://creativecommons.org/licenses/by-sa/3.0/legalcode

Vinyl-asbestos-floorings, Dunloplan - Image source Wikimedia Commons Tim Ebert (tebert) (https://commons.wikimedia.org/wiki/File:Dunloplan_Pastell-Polyflex.jpg), „Dunloplan Pastell-Polyflex“, https://creativecommons.org/licenses/by-sa/3.0/legalcode

In the 70ties asbestos-containing floorings had a market share of approx.. 20%. The various types of floorings have the following properties.

- Vinyl-asbestos tiles, floor-flex-tiles

Mostly grey or tinged with brown, square and even single tiles without a backing layer which contain about 15 % of tightly bound asbestos. Dark brown bituminous glues, that were used may contain asbestos as well. If besides the tiles the potentially asbestos-containing black layer of bituminous glue is to be removed special protection measures have to be taken. - Cushioned vinyl flooring

Rolls of expanded PVC flooring with a backing layer of white or light grey asbestos boards. The asbestos layer of only a few mm consists of approx. up to 90% of weakly bound asbestos, in most cases compressed white asbestos – chrysotile. In 1982 the use of these tiles was banned. Cushioned vinyl floorings are not to be confused with PVC flooring from the 60ties. These have a 5 mm backing layer of jute felt, which does not contain asbestos. - Asbestos tiles

These so-called “hard asbestos tiles” made on the basis of bitumen tightly adhere to the ground. They are brittle and break easily.

Image source Wikimedia Commons: Tim Ebert (tebert), Dunloplan Pastell-Polyflex, CC BY-SA 3.0

Asbestos - Disposal

Disposal of asbestos in Germany

Asbestos-containing objects or smallest amounts of asbestos-containing household wastes are accepted by public sector recycling companies. Options for the disposal in your region:

- at recycling centres

- collection at public sector waste recycling facilities

- at landfills

- at storage facilities of asbestos

- at disposal companies specialised in asbestos-containing wastes

Asbestos-containing wastes must be collected and transported in suitable receptables which can be closed securely. Moreover they are to be labelled properly. Such wastes must be kept separately from other wastes in order to avoid mixing which would increase the amount of asbestos-containing wastes or would leave the asbestos content unknown.

Please observe your local waste disposal regulations!

Asbestos - exposure limits

The concentration of asbestos fibres in ambient air is measured in fibres per cubic metre (f m-3).

There is no upper limit of asbestos concentrations which would definitely exclude the risk of getting cancer because a small amount of fibres - below detection limit - would be carcinogenic. A lower airborne asbestos concentration however reduces the statistical risk of developing cancer.

There are the following practical concentration limits:

- 100 fibres m-3 - Clean air area

- 300 fibres m-3 - Detection limit for the analysis of collection filters according to VDI 3492

- 500 fibres m-3 (measured value) und 1000 fibres m-3 (upper Poisson limit) - success control measurements, release measurements, status – quo measurements - TRGS 519, asbestos guideline

- 1000 fibres m-3 (measured value) - for success control measurements of preliminary measures and potential evidence to protect other persons during maintenance work – TRGS 519, asbestos guideline

- 15000 fibres m-3 (measured value) - Limit for work with low-exposure level at the workplace, TRGS 519

- 100000 fibres m-3 (measured value) - Limit for work of minor extent during reconstruction work, TRGS 519

Asbestos - Identifying of ...

Asbestos occurs in a variety of bound and loosely bound asbestos products as well as in products for the building chemistry.

Even an asbestos expert cannot identify asbestos with the unaided eye or just a magnifier in most of the products. The only exception might be pure asbestos products like e.g. sprayed asbestos or weathered Eternit plates with fibre bundels of whitish chrysotile asbestos sticking out. So there is the danger of a wrong negative identification regarding many products, especially in the case of low asbestos contents.

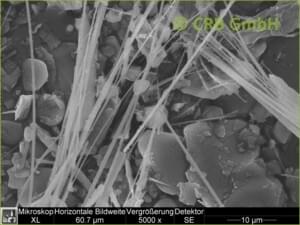

The analysis of material samples is done according to standard methods by

- Scanning electron microscopy according to guideline VDI 3866, part 5, “Determination of asbestos in technical products, Scanning electron microscopy method [2004]"

or - less common in Germany - by

- optical microscope according to VDI 3866, part 4 “Determination of asbestos in technical products. Phase contrast optical microscopy method [2002]"

Asbestos - Properties

All types of asbestos have a series of excellent chemical and physical properties. Among them are for example:

- Fibre structure

- Low density

- High elastic modulus

- Low thermal and electric conductivity

- High heat resistance

- High chemical resistance towards acids, e.g. crocidolite and bases, e.g. chrysotile

- Durability

These versatile characteristics are the reason why asbestos is used in all areas and in approximately 4.000 products.

Asbestos - Road pavements, asphalt

Road pavings, in this case asphalt, consist of a mixture of the binder bitumen and gravel from natural stones. In particular basic magmatic stones like basalt, diabase or gabbro are often used for the highly stressed surface course.

These often have a natural content of asbestos minerals from the amphibole family like actinolite, tremolite, anthophyllite, amosite (grunerite).

Asbestos fibres may be released by mechanical stress during pavement cutting, especially cold planing of paved traffic areas and recycling or re-used in road construction. They are a potential health hazard for workers, residents and road users.

Technical rule TRGS 517 describes safety measures concerning the working process with naturally asbestos-containing mineral raw materials and any product or mixture derived from them. It prescribes that IFA / BIA procedure 7487, BGIA 7487 - measures regarding the analytical determination of low mass contents of asbestos fibres in powders and dusts by SEM/EDX, figure 7487 – is to be used for the determination of the asbestos mass content.

Alternatively, according to NGS “Data sheet on the disposal of asbestos-containing waste” testing for asbestos in bitumen or tar –containing road construction waste - can be made according VDI guideline 3866, part 5.

Provided that no further fibres can be detected no further testing is necessary. If fibres can be detected according to this procedure quantification according to IFA / BIA procedure 7487 is compulsive.

Asbestos - tightly bound

Tightly bound asbestos products, cement or Eternit

- Roof coverings (flat or corrugated plates)

- exterior panelling

- pipes in all areas of building construction and civil engineering

- vent pipes and flues (gas heating)

- gardening products like flower boxes or window sills

Chemical construction products

- bitumen or roofing and sealing membranes

- floor tiles (flex tiles), adhesives

- lutings or even putties

- joint fillers

- fillers and sealants

- coating compounds, anti-corrosion coatings (water engineering)

- adhesives based on bitumen or resin

Asbestos - use, applications

Firefighters in protective suits - Image source Wikimedia Commons Von Bundesarchiv, Bild 183-37769-0001 / Biscan / CC-BY-SA 3.0, CC BY-SA 3.0 de, https://commons.wikimedia.org/w/index.php?curid=5428261

Firefighters in protective suits - Image source Wikimedia Commons Von Bundesarchiv, Bild 183-37769-0001 / Biscan / CC-BY-SA 3.0, CC BY-SA 3.0 de, https://commons.wikimedia.org/w/index.php?curid=5428261

Since the end of the 19th century asbestos was already used for the production of flat gaskets, glands or was braid or woven into cords, strings and fabrics. The application of asbestos multiplied at the beginning of the 20th century when the Austrian Ludwig Hatschek invented the asbestos-cement. He recognized that asbestos, cement and water could be mixed to become a material which could be easily formed and was very weather-resistant once it had air- dried. Hatschek chose the name Eternit for his asbestos-cement plates and secured it by Letters Patent. During the following years many more companies tried to produce asbestos-cement.

In 1929 the German Asbestos-Cement Company was founded in Berlin. The range of products included pipes, corrugated and flat boards, plates in small format and mouldings without coating.

The import of asbestos was not restricted. During the years 1937- 1945 raw asbestos was intensely used in the armaments industry. Due to the shortage of foreign exchange the import of raw asbestos had to be stopped during the years 1939-1949. The Eternit Company, too, had to stop its production due to the lack of raw material. They started producing again in 1950. After a modest beginning the production increased rapidly.

During the years 1979-1979 the import of raw asbestos into the West German federal states ranged around approx. 180,000 tons per annum, 70 % of it was used for the production of asbestos-cement. Approximately 10 % was used for the production of loosely-bound asbestos products, the remaining amount was used for other applications.

The use of asbestos in the GDR did not proceed as rapidly and was time-delayed. But it was also mainly processed into asbestos-cement products. Insulating sprayed asbestos was only used in the “Palast der Republik” (1975/76) which was very much of an exception: As the use of sprayed asbestos had already been banned in 1969 this could only be done in derogation of the common law.

Asbestos-containing floorings were not used at all.

Tightly bound asbestos products like asbestos-cement contain approx. 5-15 % asbestos and have a bulk density of generally more than 1.4/cm3.

Weakly bound asbestos products often contain more than 60% asbestos and its bulk density is below 1.0g/m3.

Asbestos - weakly bound

Weakly bonded asbestos products were mainly used for fire, heat and noise protection purposes and were used in buildings and vehicles like:

- sprayed asbestos or asbestos-containing spray plasters

- asbestos-containing plasters of light mortars

- asbestos-containing mats, asbestos boards

- asbestos-containing light-weight panels

- loose fill asbestos fibres

- asbestos-containing sealing strips

- asbestos-containing cords, strips, fabrics, foams

- floor tiles with a feltpaper like asbestos base, cushioned vinyls

- air ventilation ducts made of lightweight building boards

- fire dampers and fireproofing panels in fire doors

- protective curtains

- pipe clamps with inserts

- parts of night storage heaters

Asbestos analysis - bulk sample

All building materials like fibrous cement, floorings and glues are material samples that have to be analysed according to VDI 3866 part 5. 2004-10. Please refer to our price list for the costs of the analysis.

Asbestos analysis - dust sample

Dusts or weakly bound samples are analyzed as dust sample. The material to be analyzed is taken by means of a conductive adhesive pad or alternatively with an adhesive tape.

The analysis is carried out according to guideline VDI 3888, sheet 5 or semi-quantitative according to VDI 3877. You will find the costs of this analysis on our price list.

Asbestos analysis - guidelines & procedures

- BGI 505.30 (previously ZH 1/120.3) – “Procedure for the determination of mass fractions of chrysotile asbestos and amphiboles”.

- BGI 505-31 – “Procedure for the determination of respirable fibres – optical microscope method”.

- DGVU information 213-546, previously BGI 505-46, ZH1/120.46 respectively: “Air monitoring methods for the separate determination of the concentration of respirable inorganic fibres in work places -SEM method”

- IFA / BIA procedure 7487 – “Procedure for the analytical determination of low mass contents of asbestos fibres in powders, fine powders and dusts by SEM/EDX”.

- IFA / BIA procedure 7488 – “Determination of the CI-value in amorphous mineral fibres”.

- ISO 14966 – “Ambient air – Determination of numerical concentrations of inorganic fibrous particles – Scanning electron microscopy method”.

- ISO 22262-1 - Air quality - Bulk materials - Part 1: Sampling and qualitative determination of asbestos in commercial bulk materials

- ISO 22262-2 - Air quality - Bulk materials - Part 2: Quantitative determination of asbestos by gravimetric and microscopical methods

- Guideline VDI 3492 “indoor air measurement – ambient air measurement – measurement of inorganic fibrous particles – scanning electron microscopy method”

- Guideline VDI 3861, part 2 “Stationary source emissions: Measurement of inorganic fibrous particles in exhaust gas – Scanning electron microscopy method”.

- Guideline VDI 3866, part 1 – “Determination of asbestos in technical products – Principle, sampling and sample preparation”.

- Guideline VDI 3866, part 2 – “Determination of asbestos in technical products – Infrared spectroscopy method”.

- Guideline VDI 3866, part 4 – “Determination of asbestos in technical products – Phase contrast optical microscopy method”.

- Guideline VDI 3866, part 5 – “Determination of asbestos in technical products – Scanning electron microscopy method”.

- Guideline VDI 3877 – “Indoor pollution – Measurement of fibrous dust settled on surfaces – Sampling and analysis (SEM/EDX)”.

Asbestos laboratory - good choice

When choosing a supplier for your asbestos analysis there is not much to consider: Is the supplier an analysing laboratory or a merchant - see at-home testing? Is the analysing laboratory accredited by the DAkks? Does the laboratory have the relevant expert knowledge concerning asbestos analyses? In this case for example the participation in collaborative studies is a helpful criterion, if the results are published. CRB has been carrying out asbestos analyses since 1993 and has successfully participated - including additional qualification- in both of the VDI collaborative studies “3492” and has successfully and regularly passed collaborative studies of other providers.

Asbestos minerals - occurrence

![Crysotile, Callenberg, Saxonia - Image source Wikimedia Commons Leon Hupperichs [CC BY-SA 3.0 (http://creativecommons.org/licenses/by-sa/3.0)], via Wikimedia Commons | © Leon Hupperichs [CC BY-SA 3.0 (http://creativecommons.org/licenses/by-sa/3.0)], via Wikimedia Commons Crysotile, Callenberg, Saxonia | © Leon Hupperichs [CC BY-SA 3.0 (http://creativecommons.org/licenses/by-sa/3.0)], via Wikimedia Commons](/website/var/tmp/image-thumbnails/0/1435/thumb__glossar/clinochrysotile-482234.jpeg) Crysotile, Callenberg, Saxonia - Image source Wikimedia Commons Leon Hupperichs [CC BY-SA 3.0 (http://creativecommons.org/licenses/by-sa/3.0)], via Wikimedia Commons

Crysotile, Callenberg, Saxonia - Image source Wikimedia Commons Leon Hupperichs [CC BY-SA 3.0 (http://creativecommons.org/licenses/by-sa/3.0)], via Wikimedia Commons

All asbestos types are naturally occurring mineral raw materials that were already used 4000 years ago due to their properties for e.g. fire-resistant wicks for lamps, burial gowns and shatterproof ceramics/pottery.

Asbestos is a fibrous, silicate mineral made from magnesian and ferrous magmatic source rocks by complicated reaction mechanisms and under high pressure and at high temperatures.

Depending on the mineral compositions of the source rock there is a serpentine and an amphibole group.

The most important, e.g. the most frequently and commonly used asbestos of the group of serpentines is chrysotile which is also known as white asbestos. The most important and representative mineral of the amphibole group is the sodium silicate crocidolite, also called blue asbestos and the magnesian and ferrous silicate amosite, brown asbestos.

In Germany 94 % of the technically used asbestos types are white asbestos (chrysotile) and approx. 4 % are blue asbestos, crocidolite.

The remaining asbestos types split up among amosite and anthophyllite which are also minerals of the amphibole group.

Actinolite and tremolite must be mentioned as a natural component of magmatic rocks like basalt, dibase or gabbro, which are used for the production of grit for road surfaces.

The fibres of chrysotile asbestos are elastic and long and can be easily spun into yarn.

Fibres of amphibole asbestos however are brittle, break easily and can hardly be used for spinning.

The largest asbestos deposits can be found in Russia - chrysotile, anthophyllite -, Canada – chrysotile, South Africa – chrysotile, amosite, crocidolite - and China – chrysotile.

The asbestos content in the source rock of exploitable natural mineral deposits is generally between 4 and 10%. The processing of the “asbestos ore” is done by splitting and grinding. Then the fine fibres are separated by winnowing

Bildquelle Wikimedia Commons: Leon Hupperichs, Clinochrysotile-482234, CC BY-SA 3.0

Asbestos test set, Sampling kit

Even if these kits appear practical at first, CRB deliberately refrains from sending so-called sampling kits. On the one hand, all items enclosed with these kits are components of everyday use: razor blade/cutter, sample bag and envelope for return. You can buy a dust mask (sufficient for asbestos) for just a few € at any DIY store - but be careful: if asbestos fibres actually get into the air, the mask will only be of use to you personally and only for the moment you wear it. Asbestos fibres can float in the air for days and be inhaled by anyone entering the room. Our recommendation: Soak the sampling point in water and/or spray water onto the sampling point with a spray bottle during sampling. On the other hand, we consider such kits to be neither ecologically nor economically justifiable. Sending banal everyday objects in specially made boxes at an extra charge of up to 50€ for analysis through the whole Republic cannot be right.

Asbestos, mineralwool - Laws, directives

- Ordinance on Hazardous Substances – Workplace Safety Act – in adaption to REACH regulation

- Commission Directive 97/69/EC of 5 December 1997 adapting to technical progress for the 23rd time Council Directive 67/548/EEC on the approximation of the laws, regulations and administrative provisions relating to the classification, packaging and labelling of dangerous substances

- TRGS 402 - Identification and assessment of the risks from activities involving hazardous substances: inhalation exposure

- TRGS 420 - Process- and substance-specific criteria (VSK) for identifying and assessing inhalation exposure

- TRGS 517 – Operating on potentionally asbestos-containing materials, preparations and products

- TRGS 519 - Asbestos Demolition, reconstruction or maintenance work

- TRGS 521 - Demolition, reconstruction and maintenance work with biopersistent mineral wools

- TRGS 619 - Substitute materials for aluminium silicate wool products

- TRGS 900 - National occupational exposure limits

- TRGS 905 – National CMR Table - Carcinogenic, Mutagenic or Toxic for Reproduction

- TRGS 954 – Recommendations for granting exemptions from § 15a para. 1 GefStoffV for handling mineral raw materials and products containing asbestos in quarries

Please find all listed documents in the downloadarea of our site.

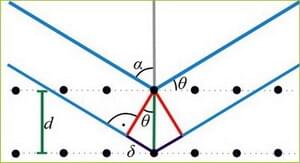

Bragg's law

Bragg's Law - Image Source Wikimedia Commons Von Dipl.-Phys. (JPG-version), Matthias M. (SVG-version) - /home/matthias/Desktop, Gemeinfrei, https://commons.wikimedia.org/w/index.php?curid=3528588

Bragg's Law - Image Source Wikimedia Commons Von Dipl.-Phys. (JPG-version), Matthias M. (SVG-version) - /home/matthias/Desktop, Gemeinfrei, https://commons.wikimedia.org/w/index.php?curid=3528588

If X-rays hit a crystal it is penetrated without obstacle by the vast part of the radiation but it can also be observed that a part of the radiation is distracted by the crystal – a phenomenon that is called X-ray diffraction.

The source of X-ray diffraction is the reflexion of X-ray at the internal layers of the crystal which behave like semi-permeable mirrors, the so-called lattice planes. Only if the conditions of Bragg’s Law are met a reflection can be observed.

n λ = 2d sin(θ)

Here n is any integer, d is the spacing between diffracting lanes, θ is the incident angle and λ is the wavelength of the beam.

Image source Wikimedia Commons: https://commons.wikimedia.org/wiki/File%3ABragg.svg

Carcinogenic index CI - Kanzerogenitätsindex, CI

According to German TRGS 905 the Kanzerogenitätsindex is one of many criteria to classify man-made mineral fibres, MMMF or mineral wools with regard to their carcinogenic potential.

Further criteria are: WHO definition of fibres, so-called WHO fibres, the intraperitoneal carcinogenicity test, the determination of the in vivo biosolubility.

The Kanzerogenitätsindex, CI for each WHO fibre to be classified results from the difference between the sum of the mass percentages referring to 100% of the oxides of sodium, potassium, boron, calcium, magnesium, barium and twice the mass percentage referring to 100% of alumina.

CI= sum Na, K, B, Ca, Mg, Ba-oxide - 2x Al-oxide

- Vitreous WHO fibres with a Carcinogenicity Index, CI <= 30 are classified in category 1B.

- Vitreous WHO fibres with a Carcinogenicity Index, CI > 30 and CI > 40 are classified in category 2.

- There classification of vitreous WHO fibres as carcinogenic does not apply in case of a Carcinogenicity Index, CI >= 40.

Additional information on this topic under ► Analytical services / MMMF analysis

Chrysotile

It is also called white asbestos and it is a collective name for the three polytypes of minerals: clinochrysotile, othochrysotile and parachrysotile. They belong to the mineral main category of silicates, the category of phyllosilicates and the group of serpentines.

Chrysotil forms long, inner hollow fibers of chipped Mg6[(OH)8[Si4O10] layers or cylinders.

The main chrysotile deposits are in Canada, South Africa and Russia.

The most commonly used type of asbestos, among others in turnout gears, fire resistant plates, gunned plasters, paints, floorings, gaskets, brake linings, clutch linings, asbestos-cement products – plates, pipes, corrugated plates, flower boxes, vent pipes – glues, sealing material, putties, loose fill sealants, floor screed – magnesia cement, Sorel cement.

Crocidolite

It is often referred to as blue asbestos, a fibrous form of riebeckite. It is a monoclinic silicate mineral with the formula Na2(Fe2+3Fe3+2)Si8O22(OH)2.

Used in turnout gears, fire resistant plates, gunned plasters, paints, floorings, gaskets, brake linings, clutch linings, asbestos-cement products – plates, pipes, corrugated plates, flower boxes, vent pipes – glues, sealing material, putties, loose fill sealants, trowelled asbestos.

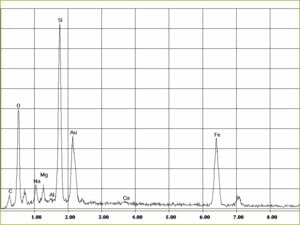

EDX - X-ray microanalysis

Its functional principle is similar to that used in energy-dispersive XRF only in this case the high-energy primary electron beam is used to excite the elements in the sample.

The characteristic fluorescence radiation emitted by each element in the sample is registered by a detector, usually a semiconductor crystal made from silicium or lithium, a SiLi-detector, or a silicium-drifted detector, SSD. By means of suitable electronic devices the signal emitted by the detector is converted in such a way that it can be analysed by a Multichannel Analyzer, MCA. It records the incoming pulses, the protons that were previously detected in relation to their amplitude, i.e. the amount of energy they are emitting. The result is an energy-dispersive element spectrum.

- Qualitative analysis via EDX spectra

There are several lines for most elements in the spectrum. With regard to the classification of lines it must be checked if all lines of a specific element are present and if their intensities are inversely proportional. At the same time peak overlaps with other elements must be considered. The energy resolution of an EDX spectrometer imposes limits on the separation of neighbouring peaks. Kα1 and Kβ2 lines of an element are commonly affected but also lines of different elements. - Quantitative analysis

The quantitative determination of the intensity of characteristic X-ray lines is done by integrating the lines and subtracting the continuous background produced by the bremsstrahlung. Initially only raw values for the mass percentages are resulting from the relative intensities of the X-ray lines of different elements, because the number of the registered characteristic X-ray quanta are depending not only on the concentration of the element but on a number of further material parameters, that are accounted for by means of ZAF corrections, a procedure in which corrections for atomic number effects (Z), absorption (A) and fluorescence (F) are calculated separately from suitable physical models.

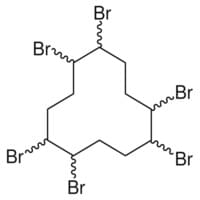

HBCD

In Germany, insulating materials made from polystyrene (PS) – Styrofoam with a content of HBCD higher than 1000 ppm are classified as hazardous waste since the 30th of September 2016 according to so-called POP-regulation, part of the Stockholm convention list and the German Waste Catalogue, Abfallverzeichnisverordnung, AVV.

What are HBCDs?

What are HBCDs?

HBCD or HBCDD (Hexabromcyclododecan, C12H18Br6) is a brominated flame retardant which was used for textiles and upholstered furniture. Its primary application was in extruded - XPS - or expanded - EPS - polystyrene foam that was used as thermal insulation.

Toxicity of HBCD and its harm to enviroment

HBCD is harmful to the environment because it is persistent and at the same time it accumulates in organism, i.e. it is bio-accumulative and has repro-toxic properties. It is ranked among the persistant organic pollutants, the so-called POPs.

Because of these properties the EC has already included it into the SVHC list, Substances of Very High Concern within the Registration, Evaluation, Authorisation and Restriction of Chemicals framework. In 2011 it was listed in REACH and is now subject to authorisation. In 2013 the substance was ranked worldwide as a Persistent Organic Pollutant according to the Stockholm convention. Since November 2014 there is a worldwide ban on its production and use.

Classification according to waste regulations

According to the POP regulation – EC No 850/2004, article 7 (2), all wastes that contain persistant organic pollutants must be disposed of in the sense that their POP content must be destroyed or irreversibly transformed.

Insulation materials are classified as containing POPs if their POP content is higher or equivalent to a certain concentration limit in Annex IV in the POP-regulation, the European Waste Catalogue, EWC or the German Waste Catalogue, Abfallverzeichnisverordnung - AVV.

The concentration limit for HBCD is 1000mg/kg and entered into force on September, 30th 2016.

Consequences

Old polystyrene insulating materials typically have HDCD contents of between 0.7% and 1.5 % and are clearly above the concentration limit of 1000 ppm (0.1%).

Since September, 30th 2016 HBCDs are classified as hazardous and require verification. Moreover they must be treated in authorised waste incineration plants.

According to German Waste Catalogue Ordinance HBCD containing waste of thermal insulators is therefore assigned to waste classification code number “17 06 03* other thermal insulators that consist of or contain hazardous substances” as of September, 30th 2016.

Testing for the presence of HBCD

Testing for the presence of HBCD

Das German Federal Environmental Agency, Umweltbundesamt describes a quick test on the basis of XRF-analysis developed by Fraunhofer Institut IVV and BASF SE.

For this test HCBD is extracted from the insulation material with an organic solvent. Afterwards its concentration in the solution/ in the insulation material is determined with high precision by means of a handheld XRF.

Mineral wool, MMMF

MMMF is the acronym of man-made mineral fibres.

Man-made mineral fibres describe an inorganic fibrous material manufactured mainly from glass and rock using recycled material like waste glass. Very often binders are used, either synthetic resins to stabilize the form of the insulating material or oils for adhesion to prevent fibre releases. Specific mineral wool products are stone wool, basalt wool, slag wool and glass wool, so-called man-made vitreous fibres, MMVF.

General information on man-made mineral fibres, MMMF

- Mineral wools with the date of manufacture 1995 and earlier

All mineral fibres with the date of manufacture 1995 and earlier are considered as 'Old Mineral Wools' as defined by technical rule TRGS 521 and are therefore to be classified as hazardous according to TRGS 905. - Mineral wools with the date of manufacture 1996 until 30 May 2000

Mineral fibres that have been marketed between 1996 and mid-2000 might have been exonerated by biocompatibility tests or are classified as “New Mineral Wools” and not as CI 40 fibres and meet the criteria for exoneration from carcinogen classification according to the Ordinance on Hazardous Substances. - Mineral wools with the date of manufacture 1 June 2000 or later

All mineral fibres which have been marketed since 1 June 2000 have passed the relevant biocompatibility tests according to EU Law or German law and are considered as “New Mineral Wools” as defined by technical rule TRGS 521 and are therefore classified as non-hazardous.

Mineral wools with an unknown date of manufacture

-

German sets of rules and regulations for built-in mineral wools with an unknown date of manufacture, without RAL Quality Mark or the evidence of biosolubility provide no possibility to differentiate between so-called old and new mineral wools.

-

A carcinogenicity test according to paragraph 3 or the determination of the in vivo biosolubility according to paragraph 4, chapter 2.3 TRGS 905 is barely possible in the case of built-in mineral wools.

-

Accordingly the only assessment criteria for those mineral wools are TRGS 905, chapter 2.3, paragraph 1, WHO fibres and the Kanzerogenitätsindex CI. A footnote of TRGS 905 states the following:

“Using the Kanzerogenitätsindex CI for the determination of WHO fibres as carcinogen may have the result that WHO fibres with a CI >40 are classified as carcinogenic although a cancerogenicity test according to paragraph 3 or the determination of the in vivo biosolubility, chapter 4 cannot lead to a classification as carcinogen. That means that WHO fibres with an index of less than 40 are to be classified as carcinogen merely for reasons of precaution although further testing might refute this classification. …”

Conclusions

A subsequent liability declaration of built-in mineral wool by means of biosolubility tests is not possible. The assessment of old mineral wools according to TRGS 521 or of such mineral wools with an unknown date of manufacture is based on German regulations (TRGS 521, TRGS 905) by testing for respirable WHO fibres and the determination of the Kanzerogenitätsindex CI provided that they are not generally classified as carcinogenic.

For further information on this topic, please see Analytical Services / Analysis of man-made mineral fibres.

RoHS 2 directive

Introduction

EC directive 2011/65/EC (RoHS 2) which replaced the initial version Directive 2022/95/EC – RoHS 1 on January 3rd, 2013 aims at banning hazardous substances like lead –Pb, mercury – Hg, cadmium – Dc, hexavalent chromium – Cr6+, polybrominated biphenyls – PBB as well as polybrominated diphenyl ether – PBDE in electrical and electronic equipment.

On March 31st, 2015 further elements like phthalates which are used e.g. as plasticisers were included.

Which products are affected by the new RoHS directive?

According to Article 3 (1) 2011/65/EC the directive shall apply to “electrical and electronic equipment’ or ‘EEE’ means equipment which is dependent on electric currents or electromagnetic fields in order to work properly and equipment for the generation, transfer and measurement of such currents and fields …” in the following categories:

- Large household appliances

- Small household appliances

- IT and telecommunications equipment

- Devices of consumer electronics

- Lighting equipment

- Electrical and electronic tools

- Toys, leisure and sports equipment

- Medical devices

- Monitoring and control instruments

- Automatic dispensers

- Other electric and electronic equipment, EEE, not covered by any of the categories above

Substances and maximum concentration values

Folgende Grenzwerte gelten für jeden „homogenen Werkstoff“ eines Artikels. Ein homogener Werkstoff ist gem. Artikel 3, Absatz 20, 2011/65/EU ein „Werkstoff von durchgehend gleichförmiger Zusammensetzung oder ein aus verschiedenen Werkstoffen bestehenden Werkstoff, der nicht durch mechanische Vorgänge wie Abschrauben, Schneiden, Zerkleinern, Mahlen und Schleifen in einzelne Werkstoffe zerlegt oder getrennt werden kann.“

| Substance | Limit value | Applications |

|---|---|---|

| Lead, Pb | 0,1 % |

|

| Mercury, Hg | 0,1 % |

|

| Cadmium, Cd | 0,01 % |

|

| Chromium VI, Cr+6 | 0,1 % |

|

| Polybrominated Biphenyls (PBB), Polybrominated Diphenylethers (PBDE) |

je 0,1 % |

|

Screening for Pb, Hg, Cd, Cr+6, Br by means of XRF analysis according to DIN EN 62321-3-1:1:2014-10

DIN EN 62321 describes the screening analysis of five substances, specifically lead (Pb), mercury (Hg), cadmium (Cd), total chromium (Cr) and total bromine (Br) in uniform materials found in electro- technical products, using the analytical technique of X-ray fluorescence (XRF) spectrometry.

This analysis can be applied to polymers, metals and ceramic materials. The test procedure applies to raw materials, individual materials removed from products and “homogenized” mixtures made up of more than one material.

The analysis by means of XRF-screening provides information on the total quantity of each element contained in the specimen; it does not identify compounds and does not provide evidence on the valence of the elements. That is why special care must be taken concerning the screening analysis of chromium and bromine, as the result only shows total chromium and total bromine. The presence of hexavalent chromium – Cr (VI) or polybrominated flame retardants, PBBs, must be verified by means of other test procedures.

SBH-method

The SBH-method is a procedure developed by the Schulbau Hamburg and has been successfully implemented to analyse potentially asbestos-containing plasters and fillers.

Single or mixed samples are prepared by ashing at 450° C and acid treatment in order to concentrate the asbestos content in the sample.

In July, 2015 the SBH-method was accounted for and described in the guideline VDI 3866. It was enlarged upon in the discussion paper Diskussionspapier des VDI und Gesamtverband Schadstoffsanierung e.V. zu Erkundung, Bewertung und Sanierung asbesthaltiger Putze, Spachtelmassen und Fliesenkleber in Gebäuden von Juni 2015 (“On exploration, evaluation and restructuring of asbestos-containing plasters, fillers and tile adhesives in buildings”, published 2015 by VDI and Gesamtverband Schadstoffsanierung e.V.).

We have been analysing critical materials for years using this preparation and examination method and have gained plenty of experience.

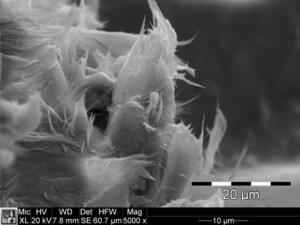

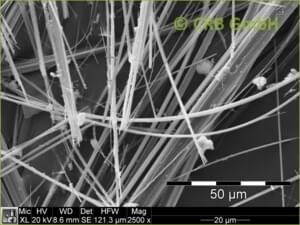

Scanning electron microscopy, SEM

Electron beams are generated in an electron source, the so-called electron gun. Basic SEMs are fitted with a filament made of wolfram, which looks like a bent hairpin or a LaB6 - crystal – lanthanum hexaboride. It is getting hot and emits electrons – the so-called hot cathode – which are then accelerated in an electric field to a voltage of typically between 8-30 kV.

The narrow electron beam scans line-by-line the surface of the specimen.

The beams resulting from primary and secondary electrons (see below) are converted into variations of brightness and are displayed synchronically on a computer monitor. Once all lines of an image are scanned the scanning process starts again at the upper image margin and a new image is formed.

Contrasts resulting from secondary electrons: The most commonly used source of information is the secondary electrons, SEs. These are generated in interdependence with the atoms of the specimen to be analysed. The energy they emit is only about a few eV as their origin is within the upper nanometres below the surface. They image the topography of the specimen.

Contrasts resulting from backscattered electrons: Another common means of image formation is the detection of backscattered electrons, BSEs. These are primary electrons that were backscattered by the specimen and show a characteristic energy pattern of only a few keV as the signal is related to the atomic number of the material to be analysed. The intensity of the signal depends mainly on the average atomic number of the specimen. Heavy elements backscatter electrons more strongly so that the relevant areas in the image are bright. Those areas presenting light elements are darker. The BSE images show the contrasts of the materials resulting from their differing illuminations. They also allow conclusions to be drawn about the chemical composition of the specimens and the distribution of different materials or elements in the picture.

Tremolite

Monoclinic amphibole asbestos with the chemical formula Ca2(Fe2+,Mg)5[OH|Si4011)2.

High-magnesium mixed crystal made from ferrous actinolite – tremolite – series of mixed crystal.

Application like amosite.

Can be contained in road pavings as a natural component of magmatic rocks like basalt, dibase or gabbro, which are used for the production of grit.

WHO fibres

The World Health Organization – WHO characterised the properties of these bio persistent fibres. Fibres with a length > 5 µm, a diameter < 3µm and a length – to – diameter ratio of > 3:1. This refers to inorganic fibres consisting of glass, rock, slag or ceramics except asbestos fibres. See TRGS 905.

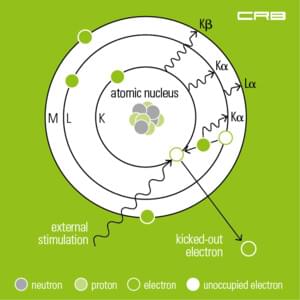

XRF - Basics of X-ray fluorescence analysis

XRF is employed for the qualitative and quantitative analysis of liquids and solids in order to determine their chemical composition. It is frequently used in the metal industry for examining glass, ceramics, building materials as well as for analysing lubricants and mineral oil products. Practical detection limits are around a few mg/kg.

XRF is employed for the qualitative and quantitative analysis of liquids and solids in order to determine their chemical composition. It is frequently used in the metal industry for examining glass, ceramics, building materials as well as for analysing lubricants and mineral oil products. Practical detection limits are around a few mg/kg.

In X-ray analysis the material to be analysed is excited by a primary source, i.e. by polychromatic X-rays, gamma or ion radiation generated in the X-ray tube. Excitation by an electron beam/cathode ray is used in X-ray microanalysis, EDX.

During the measurement inner-shell electrons located near the nucleus are raised to the outer shell. As a result electrons from higher energy levels fill the vacancies. The excess energy which was created during this process is given up as an X-ray. Thus every element has its characteristic fluorescence radiation consisting of one or more fluorescence lines with a specific energy level – compare Mosley’s Law.

Depending on its construction and the way fluorescence radiation is detected there are energy-dispersive and wavelength dispersive spectrometers.

XRF - Energy dispersive X-ray fluorescence analysis, EDXRF

As in case of WDXRF, the excitation of the elements in the sample is also achieved by primary radiation of an X-ray tube – compare XRF analysis – basics.

The characteristic fluorescence radiation emitted by each element in the sample is registered by a detector, usually a semiconductor crystal made from silicium or lithium, a SiLi-detector, or a silicium-drifted detector, SSD.

By means of suitable electronic devices the signal emitted by the detector is converted in such a way that it can be analysed by a Multichannel Analyzer, MCA.

It records the incoming pulses, the protons that were previously detected in relation to their amplitude, i.e. the amount of energy they are emitting.

The result is an energy-dispersive element spectrum.

Using suitable evaluation software, the elements of the sample and their concentrations can be determined on basis of the data obtained during the detection process.

XRF - fused beads

Quantitative analysis of a fused bead for 12, 16, 20 or 40 elements according to DIN ISO 12677:2012, DIN EN 15309:2007

For the analysis of oxide and oxidizable samples composed of a wide range of different materials such as, for instance, glass and glass fibres, soils, rock, mineral raw materials, ceramic or mineral-bonded construction materials etc.

This process involves adding a flux, lithium tetra borate, to the sample material, followed by fusing in an oxidizing atmosphere after which the sample is rapidly cooled down to form a homogenous fused bead, which is then analysed with utmost precision.

XRF - Pressed powder pellet

Especially suitable for environmentally relevant samples such as, for instance, contaminated or non-contaminated soil, clarifier sludge, refuse incineration residues, but also FGD gypsum, fly ash and other material. Owing to the type of preparation, texture and grain size effects may cause identification errors of the light major elements with atomic numbers up to 15. As far as the evaluation of raw material is concerned at least the elements ranging from Na to Si should also be additionally analyzed by fusion.

The 27-element software program is especially suitable when dealing with problems for which a specific range of elements need to be analysed, such as the LAGA or the Kloke lists, the Sewage Sludge Ordinance, or EC Directives. In environmental toxicology, however, a large number of additional elements exist which are not considered in these lists of detection limits, standard and reference values.

If a contamination with one or more of these elements is suspected or when drawing up land cadastres, we recommend that a more comprehensive measurement programme for 40 or 50 elements be chosen.

In the above cases, the material is carefully prepared as follows: the sample is dried in a drying oven at a temperature of 40°C to prevent volatilisation losses of metallic or metal-organic mercury compounds, for example, and then ground in an agate mill, unless this has already been done before supplying the material.

XRF - Screening analysis

The fundamental parameter programme Omnian provides a matrix-independent, quantitative, semi-quantitative or qualitative XRF analysis of unknown samples with a variety of material properties and different organic and inorganic compositions.

Samples can be analyzed either after preparation or without preparation and non-destructively in case of a suitable composition, i.e. X-ray and vacuum stable and depending on their surface condition.

This enables us to determine element concentrations between the minimum detection limit, usually 250 µg/g and 100%.

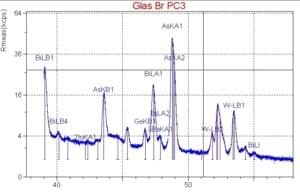

XRF - wavelength dispersive X-ray fluorescence analysis, WDXRF

Functional principle

In case of wavelength dispersive X-ray fluorescence, WDXRF, the excitation is achieved by primary radiation of an X-ray tube. The radiation emitted is collimated by parallel copper blades, diffracted by a crystal and collected in the detector.

The crystal serves to diffract the specimen’s spectrum of polychromatic secondary radiation. It allows the qualitative determination of single elements according to the diffraction angle and the quantitative determination by measuring the intensity of the secondary radiation.

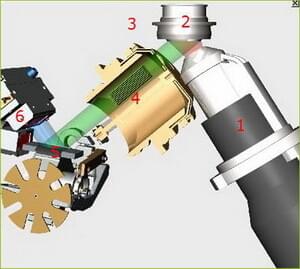

Principle of operation of a WDXRF

X-ray source (1)

Usually an X-ray tube is used as X-ray source:

- side-window type: An anode made of chrome, tungsten, molybdenum, gold or rhodium is bombarded with an electron beam. Very much heat is generated as well as X-rays which leave the X-ray tube through the beryllium window.

- An end-window type is more common due to its higher radiation density. In this case the anode is located opposite the beryllium window, the cathode is build up around the anode in a ring. When the X-ray tube is energised by a high-voltage power supply the electrons migrate towards the anode.

Specimen (2)

Tubefilter (3)

The X-ray spectrum produced by electron bombardment consists of the “bremsstrahlung”, i.e. the deceleration of electrons by the atoms in the target and the characteristic line spectrum of the material used for the anode in the X-ray tube. In order to absorb the lines of the anode a primary filter is used with an atomic number of 1 or 2 less than the anode material, e.g. a titanium filter for a Cr-Tube.

Collimator (4)

A stack of parallel metal plates (Soller plates) used for scattering, i.e. for selecting a parallel beam of rays from a diverging fluorescence radiation.

The analyzing crystal (5)

When passing the analysing crystal the polychromatic X-rays are bent in such a way, that at a certain angle of incidence/angle of reflection only radiation of a certain energy or wavelength is reflected. The basis of this principle is Bragg's law.

Detection of the fluorescence radiation (6)

The detection of fluorescence radiation is done by scintillation for heavy elements with highly energetic, short-wave characteristic radiation, and by gas flow proportional detectors for light elements with a less energetic, long-wave-characteristic radiation.

After correcting matrix effects and line overlaps, the intensity of the characteristic radiation of each element shows its concentration in the specimen.

![Mg6 [(OH) 8|Si4O10] | © CRB Analyse Service GmbH Warning: asbestos air | © CRB Analyse Service GmbH](/website/var/tmp/image-thumbnails/0/1081/thumb__glossar/warnhinweis-asbest-luft.jpeg)