X-ray fluorescence analysis, XRF of burned magnesia, burned magnesite according to DIN EN ISO 12677

Composition

Up to 99% MgO. Characterization through SiO2, CaO, Fe2O3 content and on the basis of CaO/SiO2 ratio. Density, porosity as well as crystal size of the periclase MgO are further criteria. With the addition of C as magnesia-carbon, with Cr as magnesia-chromite bricks.

Raw materials

Magnesite, MgCO3, with granular and micro crystalline structure. Magnesium chloride, MgCl2 from seawater, saltwater – natural brines and industrial waste lyes.

Application

Blast furnaces, cement and glass kilns, non-ferrous metals industry.

- ISO 29581-2:2010-03 - Cement - Test methods - Part 2: Chemical analysis by X-ray fluorescence

- DIN EN ISO 12677:2013-02 - Chemical analysis of refractory products by X-ray fluorescence (XRF) - Fused cast-bead method

- DIN EN ISO 21068-1:2008-12 - Chemical analysis of silicon-carbide-containing raw materials and refractory products - Part 1: General information and sample preparation

- DIN EN ISO 21068-2:2008-12 -Chemical analysis of silicon-carbide-containing raw materials and refractory products - Part 2: Determination of loss on ignition, total carbon, free carbon and silicon carbide, total and free silica and total and free silicon

- DIN EN ISO 26845:2008-06 - Chemical analysis of refractories - General requirements for wet chemical analysis, atomic absorption spectrometry (AAS) and inductively coupled plasma atomic emission spectrometry (ICP-AES) methods

- DIN EN 196-2:2013-10 - Method of testing cement - Part 2: Chemical analysis of cement

- DIN EN 15309:2007-08 - Characterization of waste and soil - Determination of elemental composition by X-ray fluorescence

- DIN EN 62321-3-1:2014-10 - Determination of certain substances in electrotechnical products - Part 3-1: Screening - Lead, mercury, cadmium, total chromium and total bromine by X-ray fluorescence spectrometry

- DIN 51001:2003-08 - Testing of oxidic raw materials and basic materials - General bases of work for X-ray fluorescence method (XRF)

- DIN 51001 Beiblatt 1:2010-05 - Testing of oxidic raw materials and basic materials - General bases of work for X-Ray fluorescence method (XRF) - General survey on disintegration methods referred to groups of materials for the determination of test specimens for XRF

- DIN 51081:2002-12 - Testing of oxidic raw materials and materials - Determination of change in mass on ignition

- DIN 51418-1:2008-08 - X-ray spectrometry - X-ray emission- and X-ray fluorescence analysis (XRF) - Part 1: Definitions and basic principles

- DIN 51418-2:2015-03 - X-ray spectrometry - X-ray emission and X-ray fluorescence analysis (XRF) - Part 2: Definitions and basic principles for measurements, calibration and evaluation of results

- DIN 51719:1997-07 - Testing of solid fuels - Solid mineral fuels - Determination of ash content

- DIN 51729-10:2011-04 - Testing of solid fuels - Determination of chemical composition of fuel ash - Part 10: X-Ray Fluorescence Analysis

Analytical techniques for the analysis of sinter magnesia by XRF

|

||

Quantitative XRF analysis from a fused bead

Quantitative XRF analysis from a fused bead

Standard analysis for 12 oxides, applicable to all materials without without Zr-rich samples

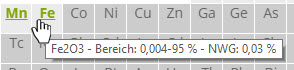

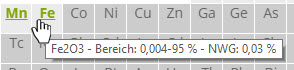

When moving the cursor over the elements highlighted in green, you will see the

- Calibration range (range) and

- the practical Limit of Detection (LOD)

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Please note:

In order to guarantee standard conformity of analysis the sample material must be ground to a grainsize < 63 µm, dried at 105°C and we need the value for the loss on ignition, LOI, as a kind of pre-preparation of the sample..

Consequently and if obligatory we carry out the sample preparation as mentioned obove - grinding, drying, determination of LOI - even though you have not explicitely ordered it.

Refer to our

► Pricelist XRF analysis

for costs and conditions.

Standard analysis for 20 oxides, applicable to all materials without without Zr-rich samples

When moving the cursor over the elements highlighted in green, you will see the

- Calibration range (range) and

- the practical Limit of Detection (LOD)

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Please note:

In order to guarantee standard conformity of analysis the sample material must be ground to a grainsize < 63 µm, dried at 105°C and we need the value for the loss on ignition, LOI, as a kind of pre-preparation of the sample..

Consequently and if obligatory we carry out the sample preparation as mentioned obove - grinding, drying, determination of LOI - even though you have not explicitely ordered it.

Refer to our

► Pricelist XRF analysis

for costs and conditions.

Quantitative analysis of a fused bead for 12, 16, 20 or 40 elements according to DIN ISO 12677:2012, DIN EN 15309:2007

For the analysis of oxide and oxidizable samples composed of a wide range of different materials such as, for instance, glass and glass fibres, soils, rock, mineral raw materials, ceramic or mineral-bonded construction materials etc.

This process involves adding a flux, lithium tetra borate, to the sample material, followed by fusing in an oxidizing atmosphere after which the sample is rapidly cooled down to form a homogenous fused bead, which is then analysed with utmost precision.

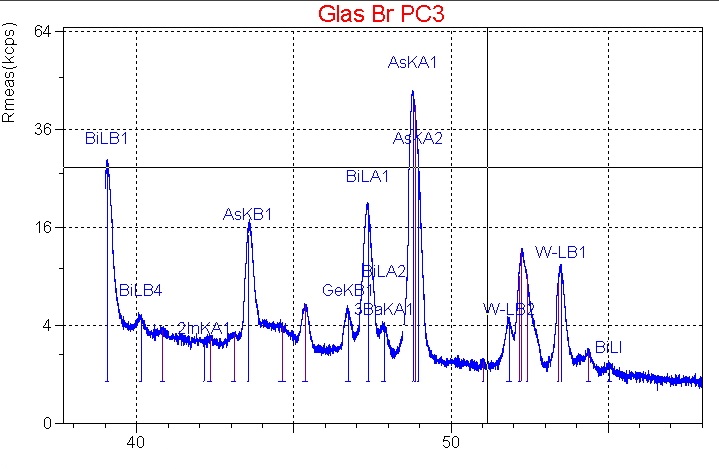

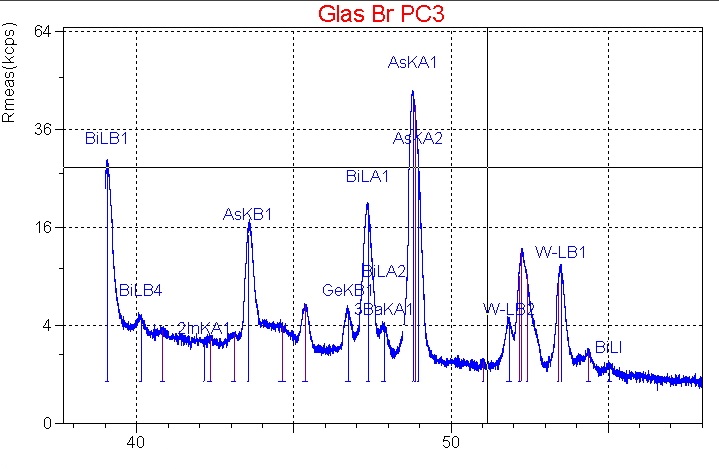

Screening analysis for 71 oxides/elements

Screening analysis for 71 oxides/elements

Screening analysis on 71 oxides/elements. Limit of detection 250 µg/g

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Please note:

In order to guarantee standard conformity of analysis the sample material must be ground to a grainsize < 63 µm, dried at 105°C and we need the value for the loss on ignition, LOI, as a kind of pre-preparation of the sample..

Consequently and if obligatory we carry out the sample preparation as mentioned obove - grinding, drying, determination of LOI - even though you have not explicitely ordered it.

Refer to our

► Pricelist XRF analysis

for costs and conditions.

The fundamental parameter programme Omnian provides a matrix-independent, quantitative, semi-quantitative or qualitative XRF analysis of unknown samples with a variety of material properties and different organic and inorganic compositions.

The fundamental parameter programme Omnian provides a matrix-independent, quantitative, semi-quantitative or qualitative XRF analysis of unknown samples with a variety of material properties and different organic and inorganic compositions.

Samples can be analyzed either after preparation or without preparation and non-destructively in case of a suitable composition, i.e. X-ray and vacuum stable and depending on their surface condition.

This enables us to determine element concentrations between the minimum detection limit, usually 250 µg/g and 100%.